I love our renewables. I love the $18.54 utility bill we receive 7-8 months of the year (darn those Ameren line fees!) when we are pushing more power back onto the grid than we are using. Considering we charge 2 electric cars regularly, this is a real achievement. We have both solar and small wind, but the solar has been the winner by far for us. A lack of moving parts makes everything substantially easier. I think the wind part may fall into the foible category!

We have 12 kW of solar, installed at two different times in two different ways. The first 6 kW was installed in June, 2012 on 2 poles mounted in the yard with an inverter in the basement. The second 6 kW was installed in November of 2015 onto our newly constructed “solar shed.” Those panels use micro-inverters, making them much easier to hook up. Ben did pretty much all of the work himself on the second set, though I did convince him to hire a few helpers to heave the panels up onto the roof and hold them in place while he attached them. I assisted with shed design and ciphering with Ben on how to run the wiring into the shed.

Here is Ben installing the rails on the standing seam metal roof of the shed. I was worried about him working on the slick roof with the slope, but we came up with a plan to install from the bottom up, so there was always a rail below to brace on and not slide off. This turned out to be important because this was happening at harvest time, and dust on a metal roof makes for a veeery slippery surface. The scaffolding also made the person who does all the worrying in the house (I wonder who that is?) feel much better.

As a side note, the matching little platform on the side of the shed has a micro-chip controlled cat door for Fuzzy so she can jump up and access the shed in bad weather. We do spoil our fuzz bucket. The builders looked at us kinda funny when we asked for it to be installed.

Here’s how the rails looked when they were mostly done. There are brackets that attach to the standing steam of the roofing and have to be torqued down to specific settings.

Here’s how the rails looked when they were mostly done. There are brackets that attach to the standing steam of the roofing and have to be torqued down to specific settings.

Now we have some action shots of the boys installing the panels. We have a lot of wind at our place, and those 3’x5′ panels can easily become a sail (even at ~45 pounds), so it helps to have extra hands.

The below shot demonstrates the advantages of being 6’4″ and having long arms when the upper bolts need to be torqued down. You can see part of one of the pole mount arrays in the left foreground of the photo.

And, now, for the [or not] part. We drove down to Southern Illinois for the eclipse several weeks ago. We wanted to be in the middle of the path of totality so we could have a long stretch of time (2.5 minutes) where the sun was totally covered. We chose to skip the crowds in Carbondale and went closer to the middle of nowhere. The weather was great, there were no clouds (although it was a bit toasty). It was amazing when the welding goggles that Ben retrofitted with the appropriate type of lens went completely black and we could take them off for a few minutes to watch the total eclipse. It was eerie how everything was dusky and the night-time bugs started making noise. It was completely worth the hours and hours of driving and traffic to see.

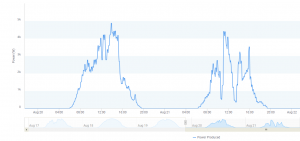

Our solar panel output also shows the eclipse. The left “bump” is a normal sunny day, and the right bump very clearly shows a dip at around the time of the eclipse where we weren’t getting much sun.

You may not be aware that New Prairie Construction is working with Champaign County for solar group buys. As of last week (2 days before the deadline for the last group buy), 290 kW of solar had been sold. At that level, the program will offset 6 tons of carbon each year, which is like planting 1,200 trees per year. While that group buy program is over, there will be more! Keep up to date on new group buy opportunities here.